KBT900 Electric Chain Tray Vacuum Sealer High Efficiency Automatic Foil Film Packing Machine for Meat Food Molds Tray Vacuum

- Model No.: KBT900

- Plastic tray dimension: Customer provides

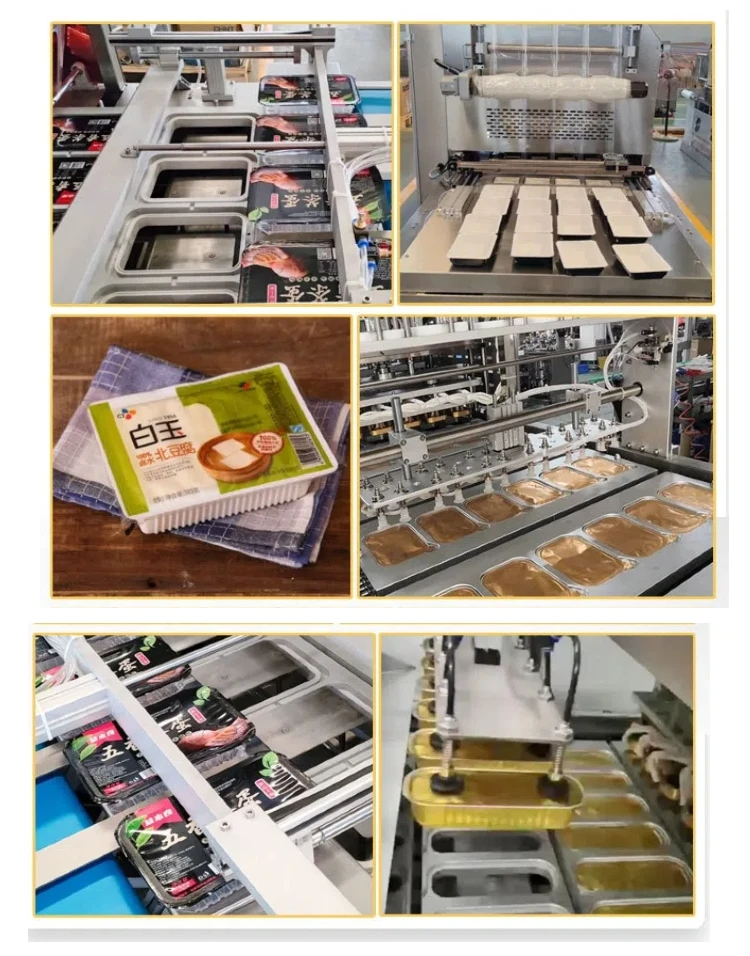

- Tray quantity per cycle: 4-8 PCs

- Vacuum pump: 3 phase, 380V, 50Hz, can customize

- Total power: 7.5-10.5 KW

- Machine dimension (mm): About 4000*900*1700

- Machine weight: About 1200 KG

- Packing speed: 1200-2400 trays/hour

- Sealing lid film roll width Max.: Customize

- Sealing lid film roll diameter Max.: 280 mm

- Compressed air: 0.6-0.8 MPa

- Overview

- Recommended Products

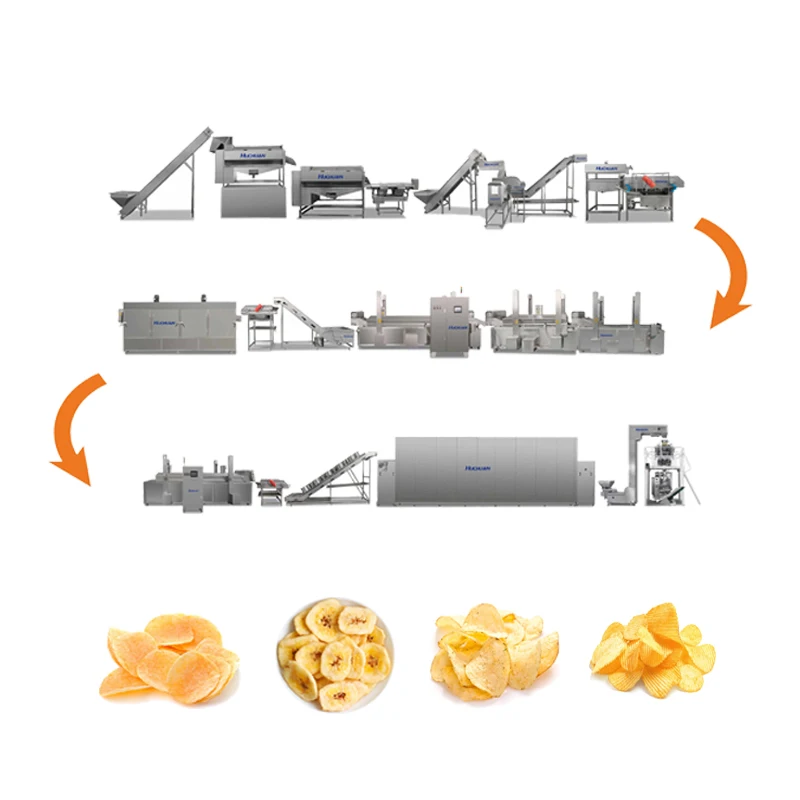

The default function of the machine is tray sealing only. MAP modified atmosphere packaging is an option if required.

KBT900 automatic tray sealer machine is compatible with different automatic filling devices, printing devices, and automatic tray feeding devices, etc, to build an automatic packaging line.

KBT900 automatic tray sealer machine features

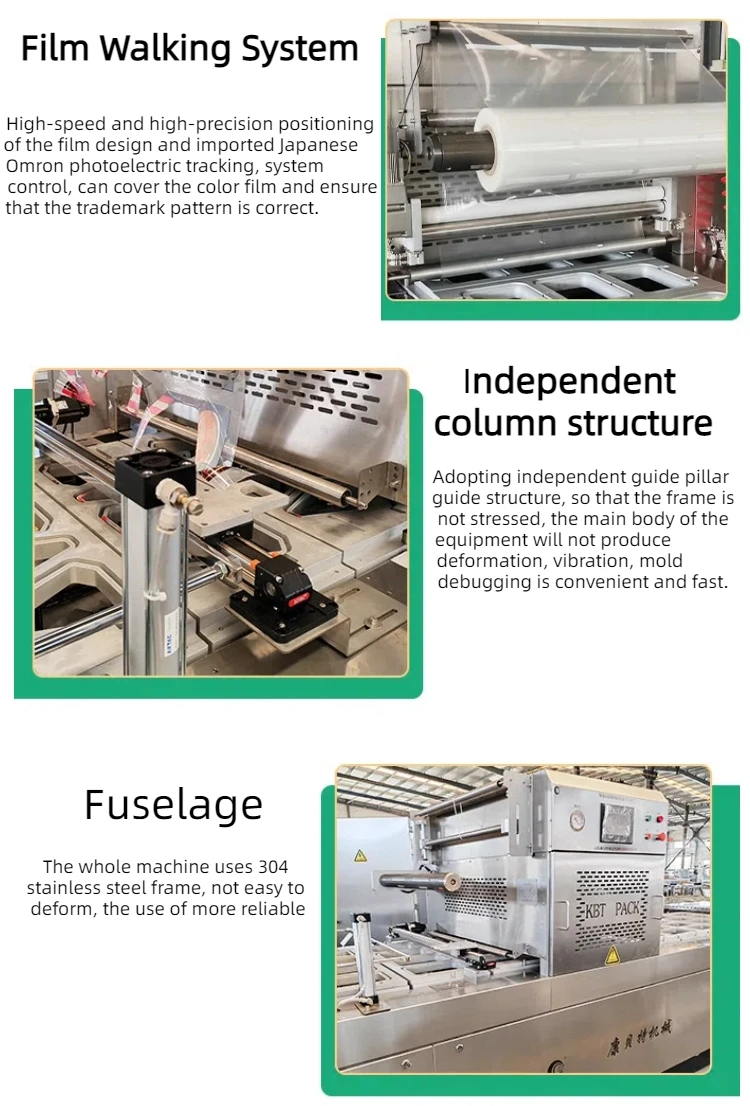

2. KBT900 automatic tray sealer machine is made of food-grade SUS304 stainless steel, inline with food hygienic

regulations,guarantees the longest service life, and best MAP packaging quality.

3. Reliable registration mark sensor for printed sealing film.

4. Safety: Equipped with emergency stop; Alarm; Open-phase protector; anti-phase protector.

6. Temperature control system: Autonics temperature control module, higher precision than temperature control button system;Overheating alarm; Split type heating plate with grids, guarantees better sealing quality.

7. Customize power supply according to customer’s request

8. Molds: Aluminum magnesium alloy molds, high strength, durable, corrosion-proof.

|

Model No.

|

KBT900

|

|

Plastic tray dimension

|

Customer provides

|

|

Tray quantity per cycle

|

4-8 PCs

|

|

Vacuum pump

|

3 phase, 380V, 50Hz, can customize

|

|

Total power

|

7.5-10.5 KW

|

|

Machine dimension (mm)

|

About 4000*900*1700

|

|

Machine weight

|

About 1200 KG

|

|

Packing speed

|

1200-2400 trays/hour

|

|

Sealing lid film roll width Max.

|

Customize

|

|

Sealing lid film roll diameter Max.

|

280 mm

|

|

Compressed air

|

0.6-0.8 MPa

|

Q2.: Do you have any certifications for your products and your company?

A2: Yes. We have CE certifications, ISO9001, ISO14001.

Q3: The power supply in my country is different from that is in China, so I'm worrying if I could use the machine in my factory?

A3: Please don't worry about this.

We customize every machine to make sure they are in accordance with your local power supply.

You can use the machines without any problem.

Q4: How long can I receive the machine if I make an order?

A4: The leading time is different, depends on machine type and production schedule.

Usually, leading time for thermoforing packaging machine is 15-30 days;

leading time for inline automatic MAP machine is 10-25 days;

leading time for vertical MAP machine and chamber vacuum packing machines are 5-15 days.

Q5: I'd like to visit your factory, how can I easily find your location, and what's the route to your factory?

A5: Your are very welcome to visit our factory.

Our location is: East end of Mizhou Road,Zhucheng High-tech Development Zone,Zhucheng City,Shandong Province

Your can easily find our location by searching 'SHANDONG KANGBEITE ' at google map.

Our nearest airport and railway station is Qingdao, a 2 hour's drive way.

It takes 2 hours flight from Shanghai to Qingdao, 4.5 hours flight from Guangzhou to Qingdao.