Huchuan 1000kg/batch Lyophilizer Freeze Dryer Industrial Machine for Milk

- Model No.: HTFD5L-0.5m²/R

- Dehydration capacity: 5L

- Heating area: 0.5m²

- Drying capacity: /

- Operating pressure (negative pressure PA): 13-133Pa(limit pressure

- Heating method(Mpa): Electrically

- Working hours(H/batch): 8-24H

- Dimensions(m): 1.2x1.2 x2.0

- Overview

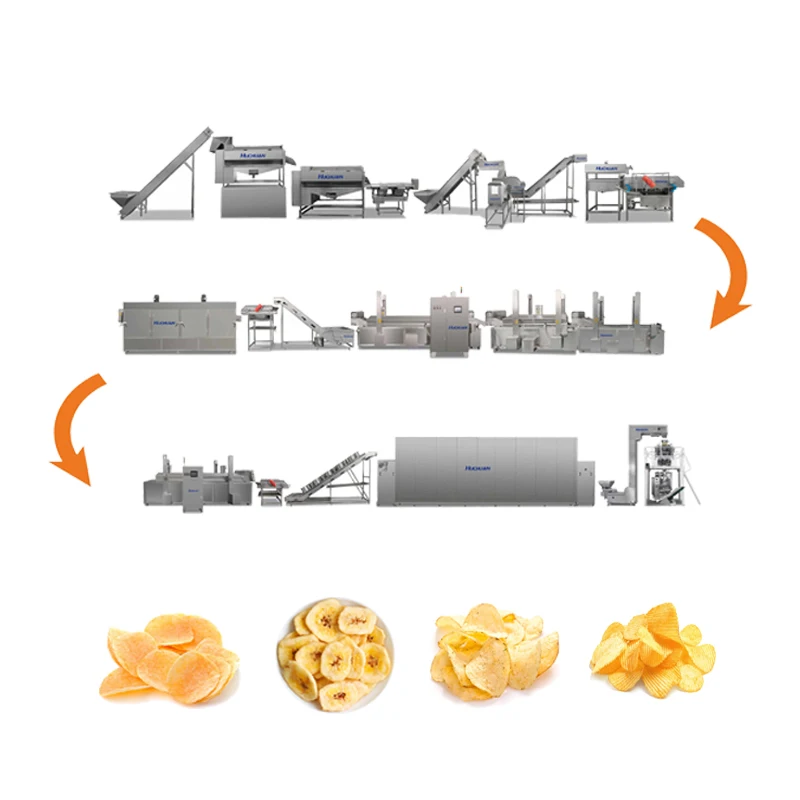

- Recommended Products

Products Description

Working principle

The basic principle of freeze-drying is based on the change of three states of water. Water has a solid, liquid and gas state, and the three states can be converted into each other and can coexist. In the high vacuum state, the principle of sublimation is used to make the water in the pre-frozen material be removed directly from the ice state to water vapor without melting the ice, so as to achieve the purpose of freeze-drying. Freeze-dried products are spongy, dry shrinkage, excellent rehydration, moisture content is very little, the corresponding packaging can be stored and transported at room temperature for a long time.

Advantages of freeze-drying machine

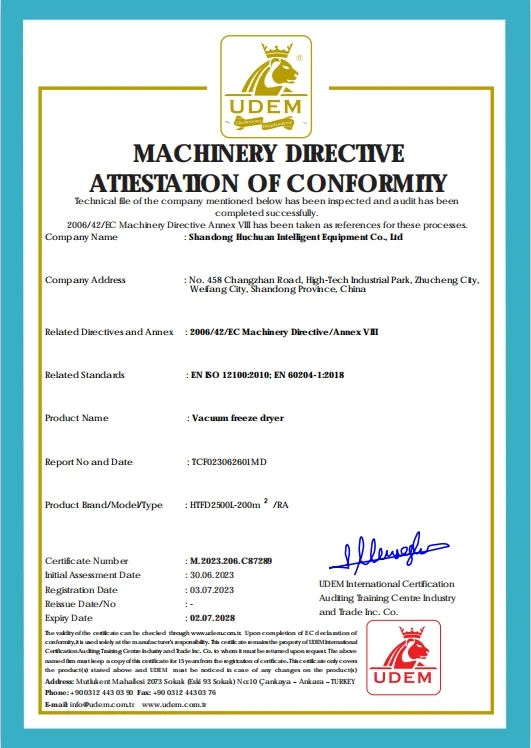

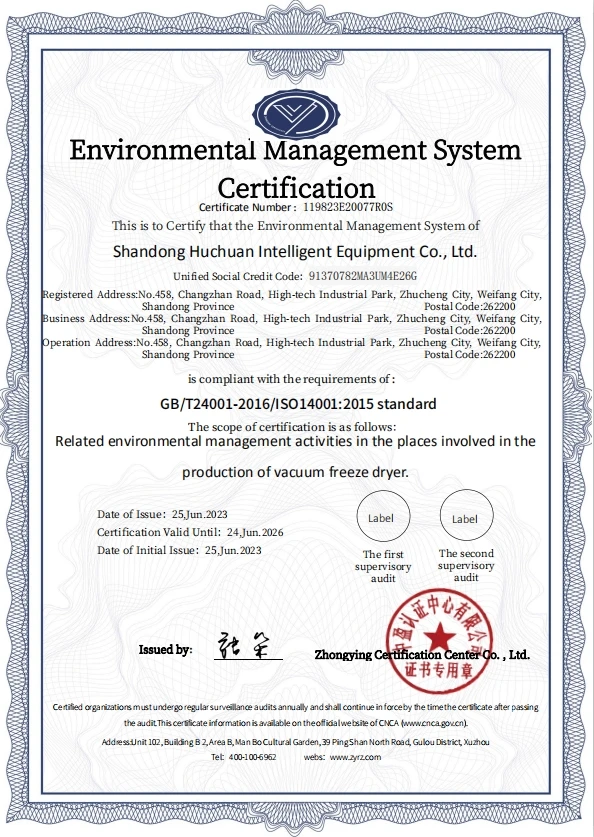

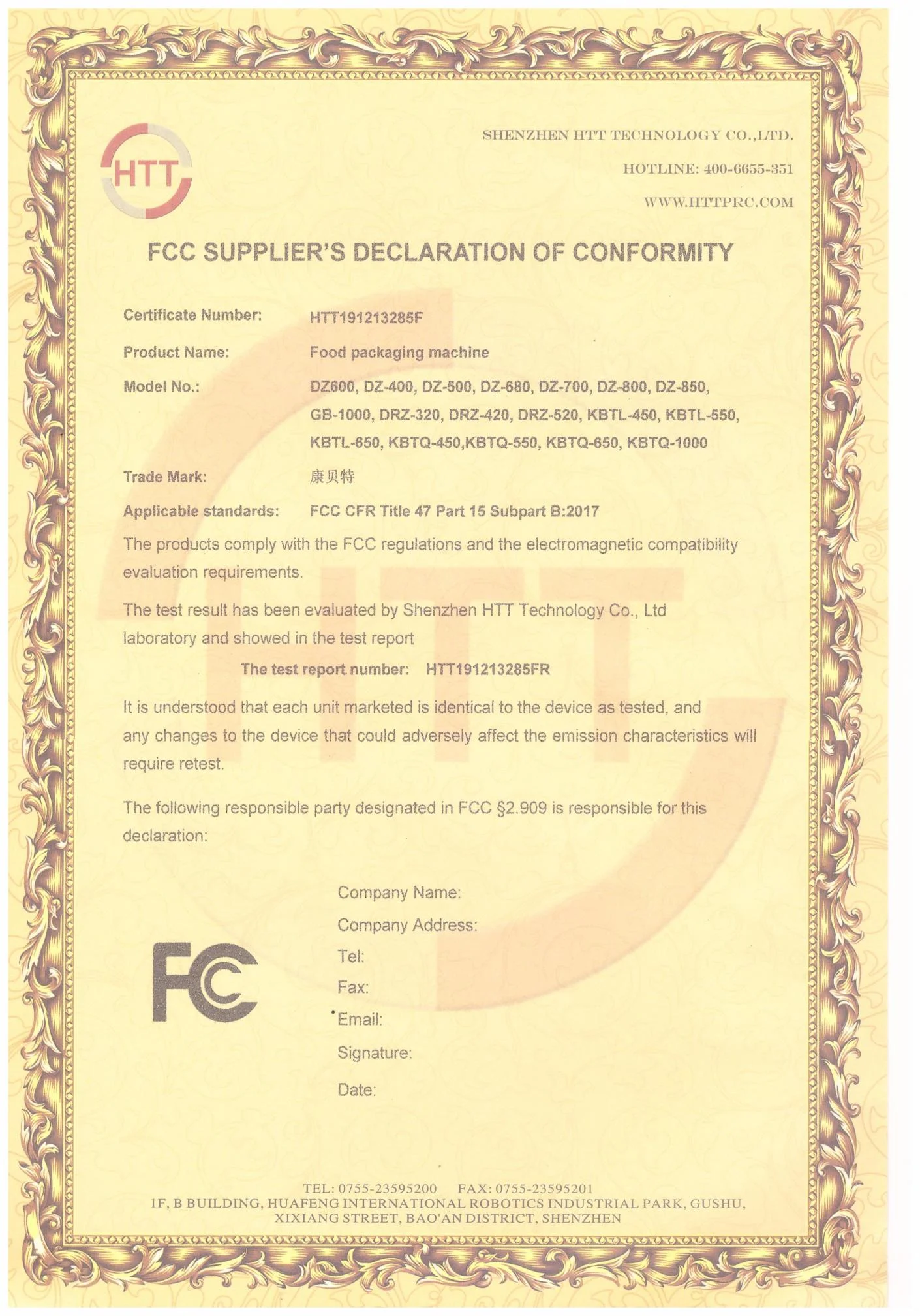

Turnkey FD plant with TOYO Giken FD Technology Freeze-dried technology since 1962, free instruction on how to produce freeze-dried products. ISO9001:2008 quality management system certification, ISO14001:2001 environmental management system certification, CE certification, UL certification. The quality of production products meets multiple certification standards: (FDA) (FSLJ) (FIS) (BRC) Engineers will install on-site overseas and respond to after-sales service within 24 hours.

Mainly suitable for large-scale enterprise production, for deep processing of agricultural and sideline products, fruits and vegetables, aquatic products, pet food, convenience food, leisure food, etc., with high production capacity, low operating costs, high profits, large drying area, and large water treatment capacity. Ice melting adopts thermal shelling+warm water defrosting or steam defrosting. Melt and discharge within 40 minutes after the batch cycle.

V-FD FOOD CHARACTERISTICS

1.Retained the original active ingredients, color, fragrance, taste, and no loss.

2.Completely retaining various nutrients such as vitamins and proteins.

3.The active ingredients quickly revive when exposed to water, rehydrate quickty, and maintain their original shape.

4.It has achieved long-term preservation, up to 3-5 years, and with slight preservationmeasures, it can last for more than 10 years.

5.Dehydrated foods and other products are lightweight and extremely convenient for storage and transportation.

|

Model No.

|

Dehydration capacity

|

Heating area

|

Drying capacity

|

Operating pressure (negative pressure PA)

|

Heating method(Mpa)

|

working hours(H/batch)

|

Dimensions(m)

|

|

HTFD5L-0.5m²/R

|

5L

|

0.5m²

|

/

|

13-133Pa(limit pressure

|

Electrically

|

8-24H

|

1.2x1.2 x2.0

|

|

HTFD50L -3m²/R

|

50L

|

3m²

|

30kg

|

13-133Pa(limit pressure

|

Electrically

|

8-24H

|

2.1x2.4 x2.0

|

|

HTFD150L-10m²/R

|

150L

|

10m²

|

180kg

|

13-133Pa(limit pressure

|

Electrically heated distilled water

|

8-24H

|

φ1.8x4.0 x3.2

|

|

HTFD300L-20m²/R

|

300L

|

20m²

|

360kg

|

13-133Pa(limit pressure

|

Distilled water/steam 0.4Mpa

|

8-24H

|

φ1.8x5.8 x3.2

|

|

HTFD450L-30m²/RA

|

450L

|

30m²

|

550kg

|

13-133Pa(limit pressure

|

Distilled water/steam 0.4Mpa

|

8-24H

|

φ1.8x7.5 x3.2

|

|

HTFD600L-50m²/RA

|

600L

|

50m²

|

650kg

|

13-133Pa(limit pressure

|

Distilled water/steam 0.4Mpa

|

12-24H

|

φ2.5x7.0 x4.0

|

|

HTFD1200L-100m²/RA

|

1200L

|

100m²

|

1300kg

|

13-133Pa(limit pressure

|

Distilled water/steam 0.4Mpa

|

12-24H

|

φ2.5x10 x4.0

|

|

HTFD2500L-200m²/RA

|

2500L

|

200m²

|

2800kg

|

13-133Pa(limit pressure

|

Distilled water/steam 0.4Mpa

|

12-24H

|

φ2.5x17.5 x4.0

|

|

HTFD3000L-240m²/RA

|

3000L

|

240m²

|

3500kg

|

13-133Pa(limit pressure

|

Distilled water/steam 0.4Mpa

|

12-24H

|

φ2.5x12.8 x4.5

|

|

HTFD3500L-300m²/RA

|

3500L

|

300m²

|

4000kg

|

13-133Pa(limit pressure

|

Distilled water/steam 0.4Mpa

|

12-24H

|

φ2.5x15 x4.5

|

Technical description:

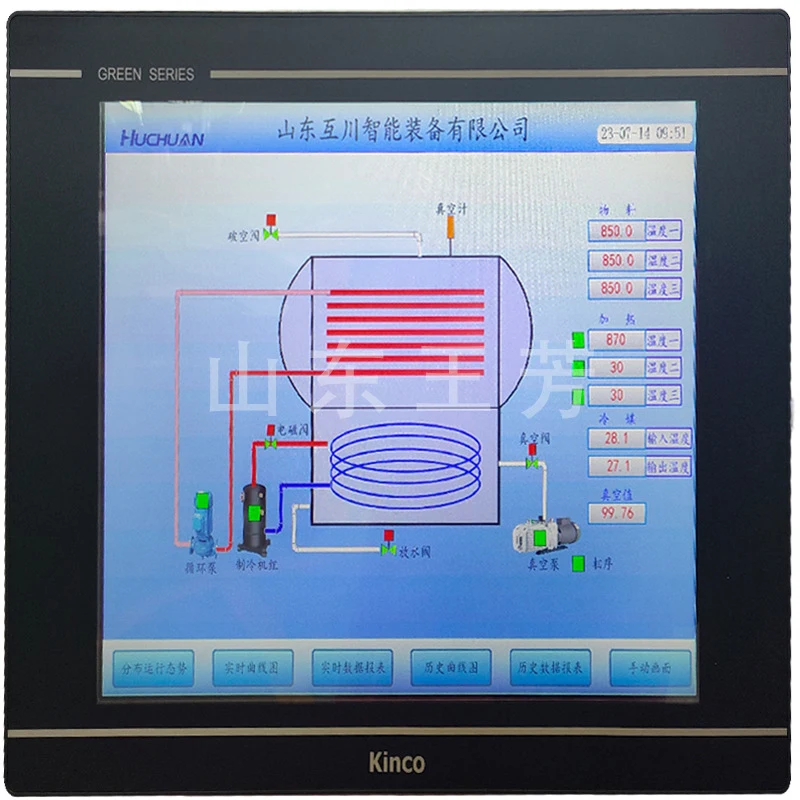

Control system: Adopting dual circuit single circuit control, manualautomatic, PLC display control/temperature control display control. Real time operation parameters/process curve monitoring printing. Key control components, PLC modules, pumps, valves, and heat exchange devices are all equipped with international first brand products from Germany, Japan, and Sweden. Refrigeration system: using open screw and semi sealed screw units, using medium; Freon and ammonia liquid are supplied in the form of direct expansion and barrel pump. In the same industry, we have a leading advantage in the design and manufacturing of FD equipment, using the design theoretical parameters and standards of Toyo Technology Research in Japan. Compared with domestic manufacturers, our design is reasonable, low in energy consumption, stable in operation, high in intelligence, and equipped with interlocking devices, ensuring safety and reliability.

Details Images

Visible window

Stainless steel, safe and reliable

Control system

PLC control constant heating/ stage heating optionalAutomatic alarm functionConnected to the computer to remotemonitor the machineAutomatic record and store freeze-dried data and curve, with data saving function.

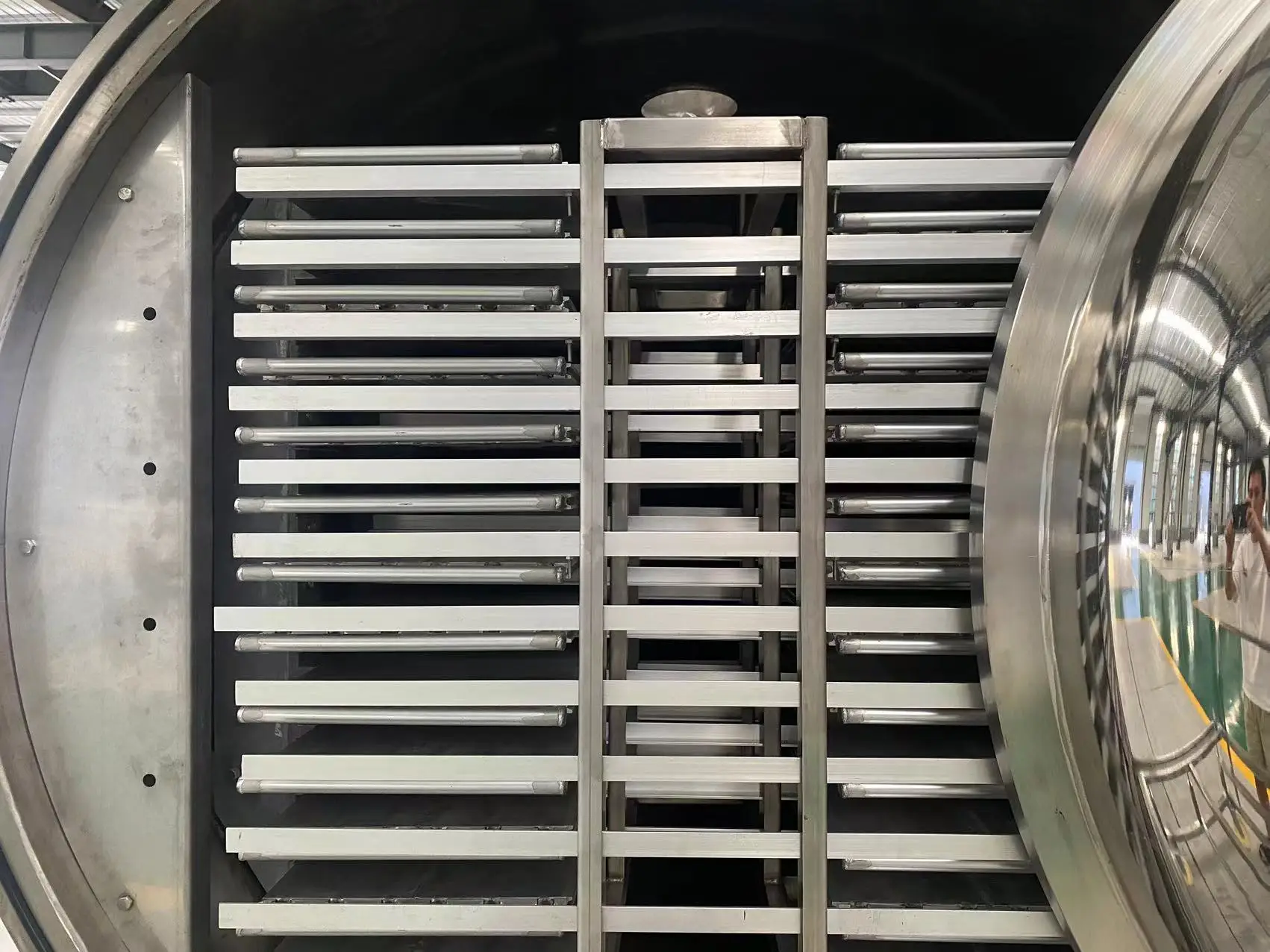

Drying chamber/ Shelf

Easy to open, PLC control shelf heating and cooling, temperature control accuracy<±1℃.Shelf heating method: constant heating /stage heating

Vacuum system, heating system, refrigeration system

The unit mainly extracts vacuum for the freeze-drying chamber, provides heat and provides cooling capacity

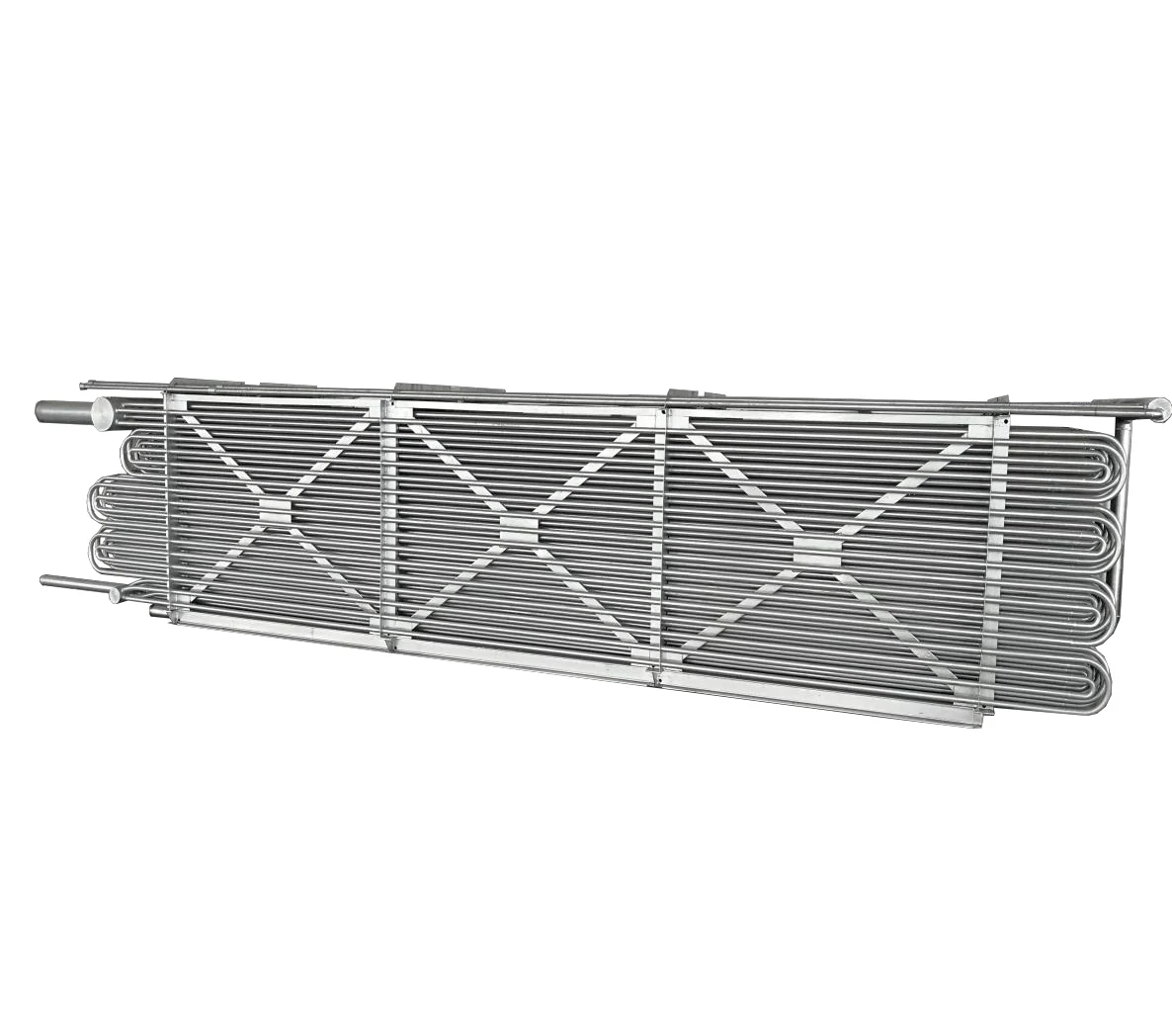

Cold trap

SUS304/316L made

Argon arc welding, forming in one stepto ensure no leakage and clean

Finished product display

V-FD MAIN SUPPORTING SYSTEMS

Raw material processing

Material freezing system

Dry system

vacuum system

Heating medium system

Refrigerant system

Pneumatic system

Ice melting system

electrical control system

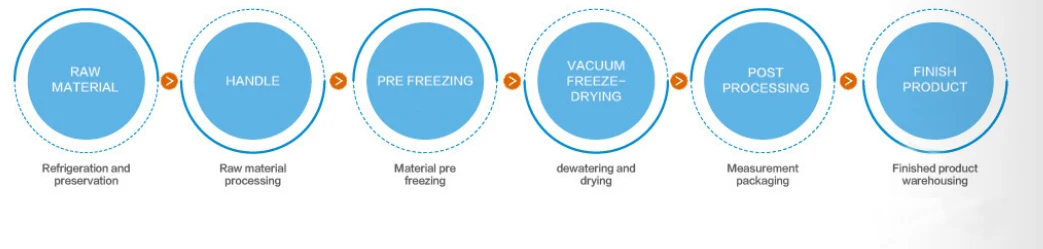

V-FD TECHNOLOGICAL PROCESS:

V-FD EQUIPMENT ADVANTAGES:

FULL PROCESS CONTROL

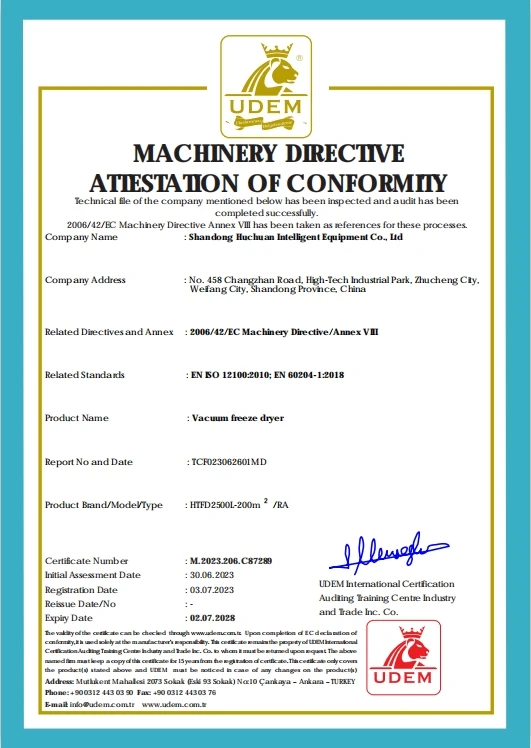

Enterprises have strict production process management, process control, quality assurance. Is GB/T190012016 / ISO9001:2015 quality system, GB/T24001-2016 / ISO14001:2015 environmental system and EN ISO 12100:2010, EN 60204-1:18 security system certification enterprises.

R&D TEAM

Interchuan intelligent equipment has a large manufacturing and processing plant of more than 40,000 square meters, the senior staff of the enterprise has been deeply engaged in the freeze-drying industry for more than 20 years, the freeze-drying process knowledge and theoretical basis, practical experience, is very professional and rich, can provide you with a full range of freeze-dried food and other solutions.

PROFESSIONAL THEORY AND TECHNOLOGY

Interchuan intelligent technology combined with Toyo technology research freeze drying advanced technology, the use of Japan, Germany's advanced freeze drying technology, the selection of Japan, Germany, the United States, Sweden and domestic advanced equipment, to achieve the perfect combination of advanced equipment and process conditions,V-FD equipment reliable operation, high efficiency, low energy consumption, intelligent, energy saving, environmental protection.

PROCESSING EQUIPMENT MAJOR

V-FD equipment manufacturing process is the key link, the designer must have professional knowledge and experience, with professional theoretical basis and process research, Interchuan intelligent equipped with freeze-drying technology experts and engineers. V-FD equipment has rich experience in design, manufacturing, assembly test, installation and debugging. High precision, high level of automation, the whole process is controlled, each process is equipped with professional quality assurance engineers and quality assurance inspection, to ensure the product quality of V-FD equipment.

Company Profile

Shandong Huchuan Intelligent Equipment Co., Ltd. is a high-tech enterprise that integrates the research and development, design, production,l sales, and service of food and pharmaceutical freeze-drying equipment and freeze-drying systems.The company has a complete administrative and quality management system, as well as EU CE certification. The overall scale covers an areal of over 100 acres, with a production workshop of over 40000 square meters. The total investment in the first phase is 260 million yuan, and the registered capital is 26 million yuan.

The company has been cooperating with Toyo Technology Research in the field of freeze-drying technology in Japan, and combining technology from Germany, Sweden, and the United States to comprehensively design supporting facilities, with production, processing, forming, inspection and testing capabilities. Excellent processing and complete testing ensure the manufacturing accuracy and processing quality ol the equipment. The equipment is stable in operation, energy-saving and efficient, and the freeze-drying process is advanced. The equipment manufacturing technology and freeze-drying process technology are leading, and the main parts are equipped with world-renowned brands. The improvement of the quality of FD equipment has brought extraordinary development and abundant profits to processing enterprises such as food, vegetables, fruits, seafood, pharmaceuticals, etc. In recent years, there has been an increase in scientific research investment, providing a good solution for preserving biological activity in many active substance products such as serum, bacterial strains, and traditional Chinese and Western medicine.

Huchuan Intelligent is a specialized company that integrates FD equipment technology design, manufacturing, installation and debugging. Thel company has multiple professional senior engineers, 120 FD equipment manufacturing and engineering technicians, 15 various management personnel, and more than 20 after-sales teams. The personnel are sufficient, and the processing equipment is complete and excellent, fully meeting the needs of equipment manufacturing, installation, debugging, operation, technical training, and other aspects.

Since its establishment, the company has always adhered to the entrepreneurial principle of "survival with quality, development with reputation". Its products are exported to more than 40 countries and regions around the country and the world. It is a strong brand manufacturer in the freeze-drying machine industry that holds core technology, and has improved technology and after-sales service. High quality after-sales service is our eternal commitment. We will do our best to develop together with our customers, advocating for energy conservation, environmental protection, and efficient intelligence as our own responsibility, with the goal of being an outstanding enterprise, and the endless pursuit of quality. We have a long way to go in catching up with and surpassing the world's leading freeze-drying equipment. We will adhere to the business philosophy of intensive cultivation, step-by-step operation, seeking progress while maintaining stability, seeking innovation through change, honesty and innovation, and win-win cooperation. We sincerely cooperate with domestic and foreign customers to achieve mutual benefit and create brilliance together!

Why Choose Us

At present, the company's research and development team has more than 60 people, and can provide customers with product customization services. Has a number of patented technologies. The equipment is energy-saving, high-quality, high-efficiency, and stable, and has been favored by many domestic and foreign catering, fishery, and medical industries.

CUSTOMER SERVICE CASES