Factory Customized CE Factory Industrial Paneer Cheese Vacuum Packing Machine

- Model No.: DZ320, DZ420, DZ520

- Top film width(mm): 295-296mm, 395-396mm, 495-496mm

- Bottom film width (mm): 322-323mm, 422-423mm, 522-523mm

- Vacuum degree (pa): <=1000

- Compressed air (Mpa): >=0.6

- Portal (mm): Φ16 PU pipe

- Cooling water (Mpa): ≧0.15

- Power supply 3Phase, 380V/50HZ,customizable

- Total Power(KW): About 13, About 15, About 18

- Speed(cycles/min): 5-7, 6-10, 5-7

- Machine weight (KG): About 1400, About 2100, About 2400

- Machine size (mm): About 6200*850*1900, About 7200*950*1900, About 8200*1050*1900

- Overview

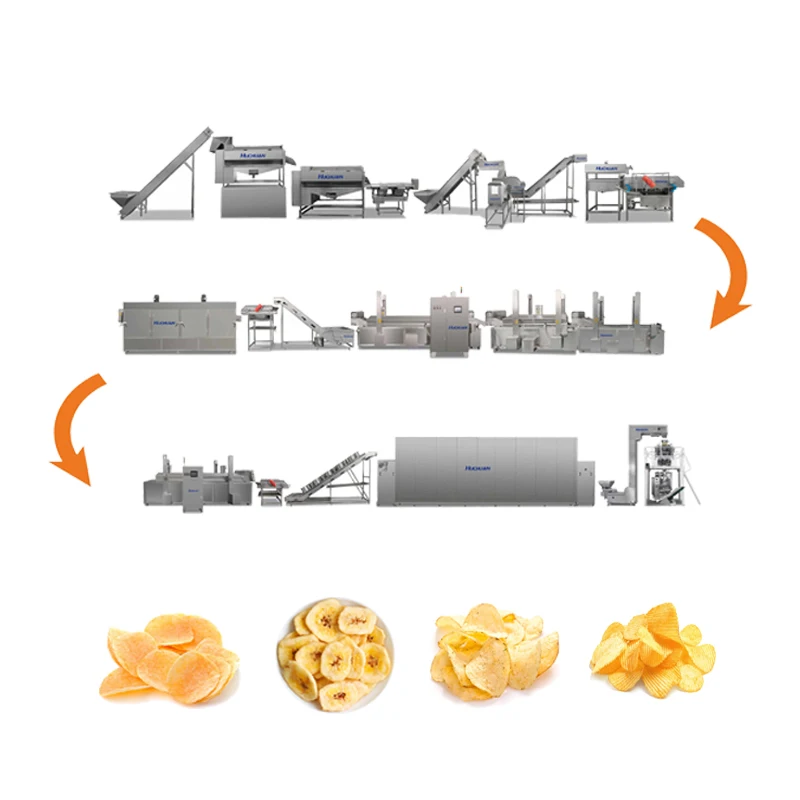

- Recommended Products

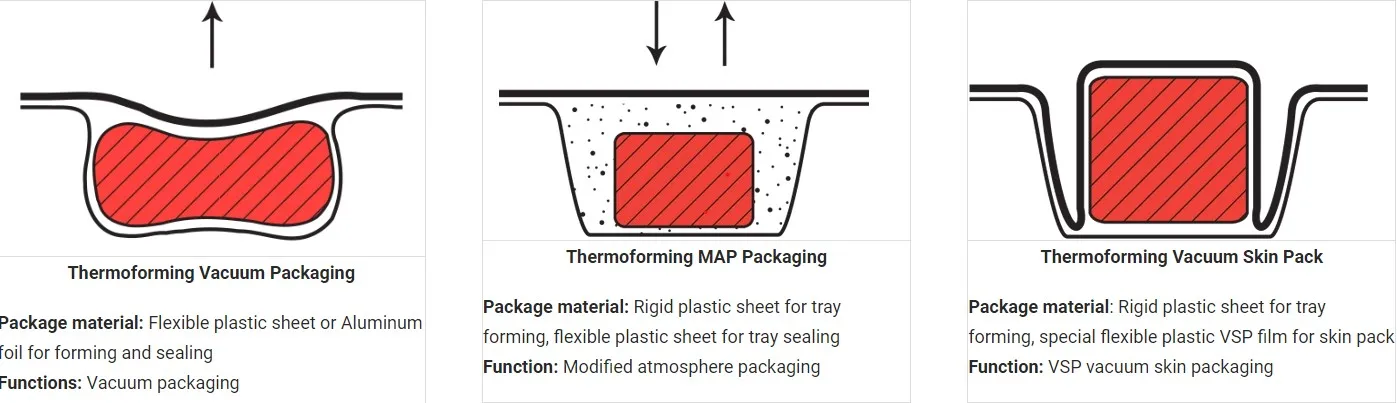

Horizontal automatic packing machines characterised by package formation within the machine using two film coils (forming/under film, sealing/upper film) normally made of different material.

Depending on the material used, packages can be flexible or rigid. This type of machine is aimed both at food and non food markets.

Pakcaging method: Vacuum packaging in flexible packs; MAP modified atmosphere packaging(nitrogen filling, mixed air filling) in flexible packs; Map modified atmosphere packaging in rigid and semi-rigid packs; VSP vacuum skin packaging in rigid packs.

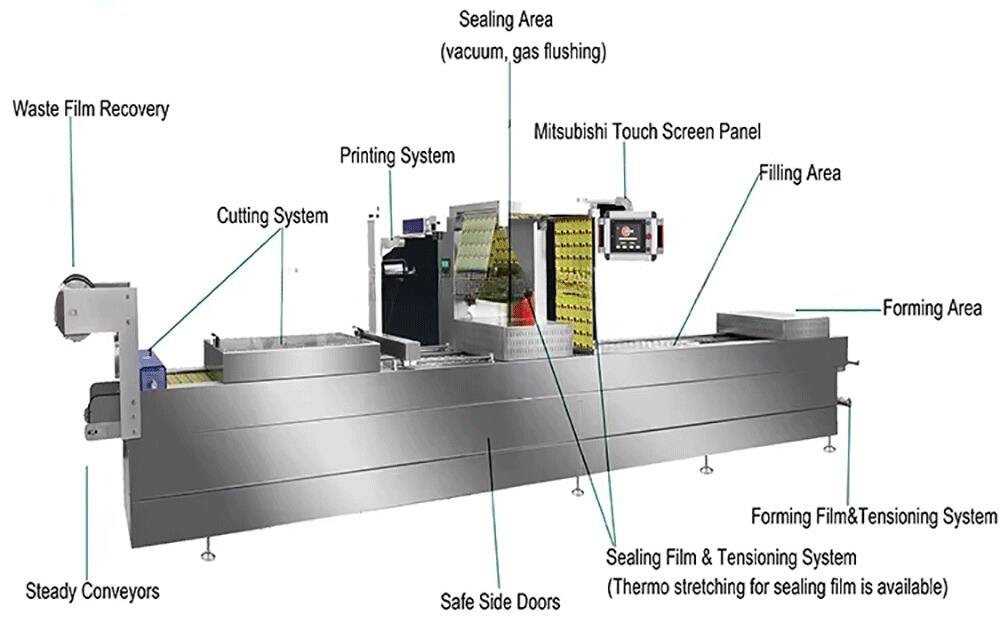

* Vacuum sealing chamber adopts 4-axis linear bearing vertical stable lifting system, German Igus linear bearing. Sealing heating plate owns 8 Airtac cylinders and positioner, which ensures vertical sealing of heating plate, smooth sealing, clear pressure pattern, no skew, perfect sealing effect, high packaging efficiency and no leakage after sterilization.

* Forming chamber, vacuum sealing chamber and cylinder lifting mechanism adopt the principle of triangular lever, with

self-locking function which ensures stable lifting.

* The equipment frame is made of high strength Al-Mg alloy, (6061-T6) extruded by 8 kiloton extruder (other manufacturer 6105 and is extruded by 2 kiloton extruder). The frame has high strength and good stability.

* The support frame is welded by Shanghai Baosteel 304 stainless steel, and processed by double-sided milling machine. It has high accuracy, good stability, no bias and film falling.

* The equipment is equipped with automatic alarm function. Each part is equipped with induction switch, which can automatically alarm and stop. Human machine interface can display and analyze the causes of the failure, so as to facilitate maintenance by engineers.

* The equipment has the function of fault memory reset. When the equipment shuts down and the fault is eliminated, the equipment will automatically memorize the program before the fault and complete the program action before the fault. In the process of using, it can save time, save the stretching film, reduce the cost of using, and improve the efficiency (Company patent).

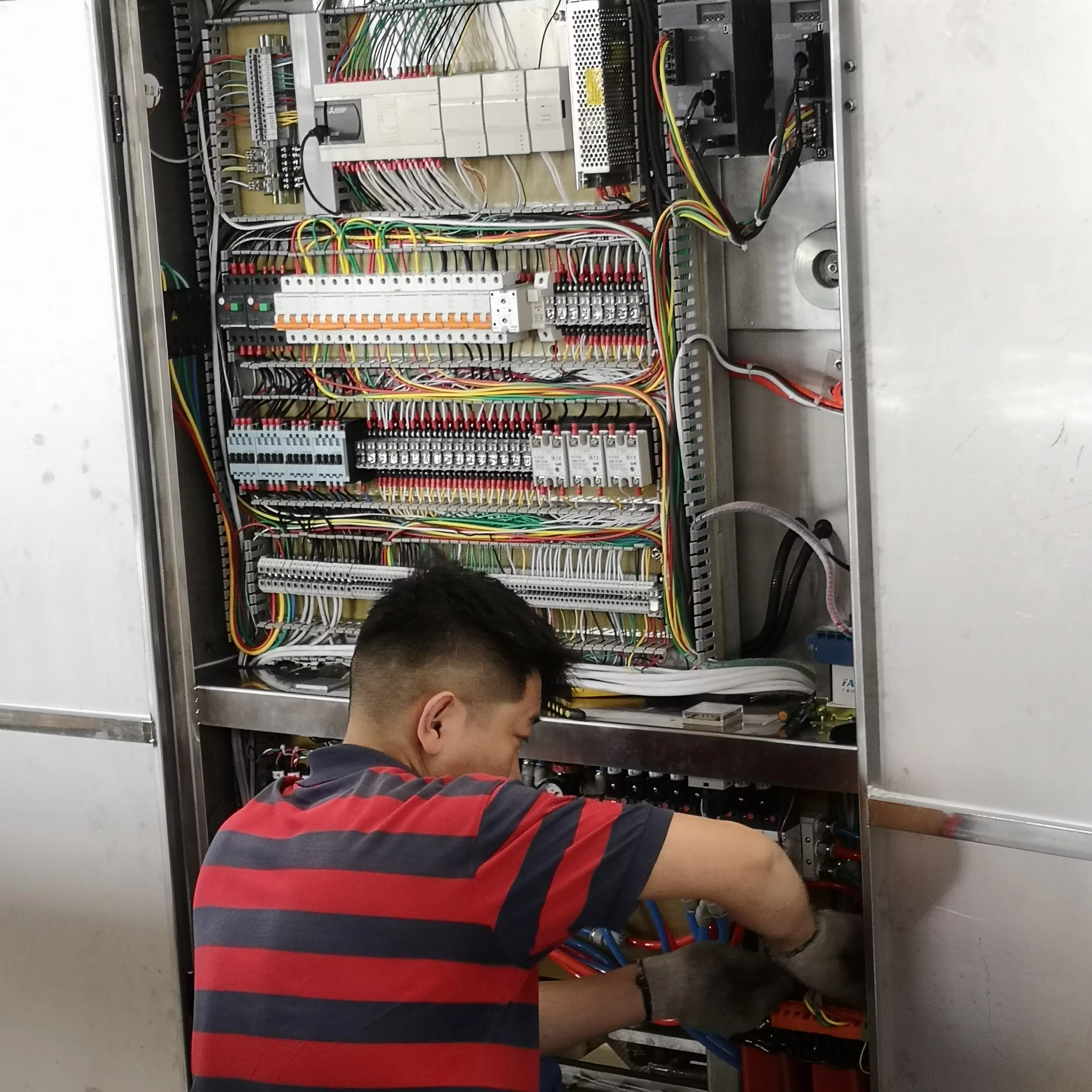

* Dry and dehumidify system is designed for electrical control system, which effectively ensures the normal operation of the equipment, especially suitable for rainy areas.

|

Item

|

Data

|

||||||

|

Model No.

|

DZ320

|

DZ420

|

DZ520

|

||||

|

Top film width(mm)

|

295-296mm

|

395-396mm

|

495-496mm

|

||||

|

Bottom film width (mm)

|

322-323mm

|

422-423mm

|

522-523mm

|

||||

|

Vacuum degree (pa)

|

<=1000

|

||||||

|

Compressed air (Mpa)

|

>=0.6

|

||||||

|

Portal (mm)

|

Φ16 PU pipe

|

||||||

|

Cooling water (Mpa)

|

≧0.15

|

||||||

|

Power supply

|

3Phase, 380V/50HZ,customizable

|

||||||

|

Total Power(KW)

|

About 13

|

About 15

|

About 18

|

||||

|

Speed(cycles/min)

|

5-7

|

6-10

|

5-7

|

||||

|

Machine weight (KG)

|

About 1400

|

About 2100

|

About 2400

|

||||

|

Machine size (mm)

|

About 6200*850*1900

|

About 7200*950*1900

|

About 8200*1050*1900

|

||||

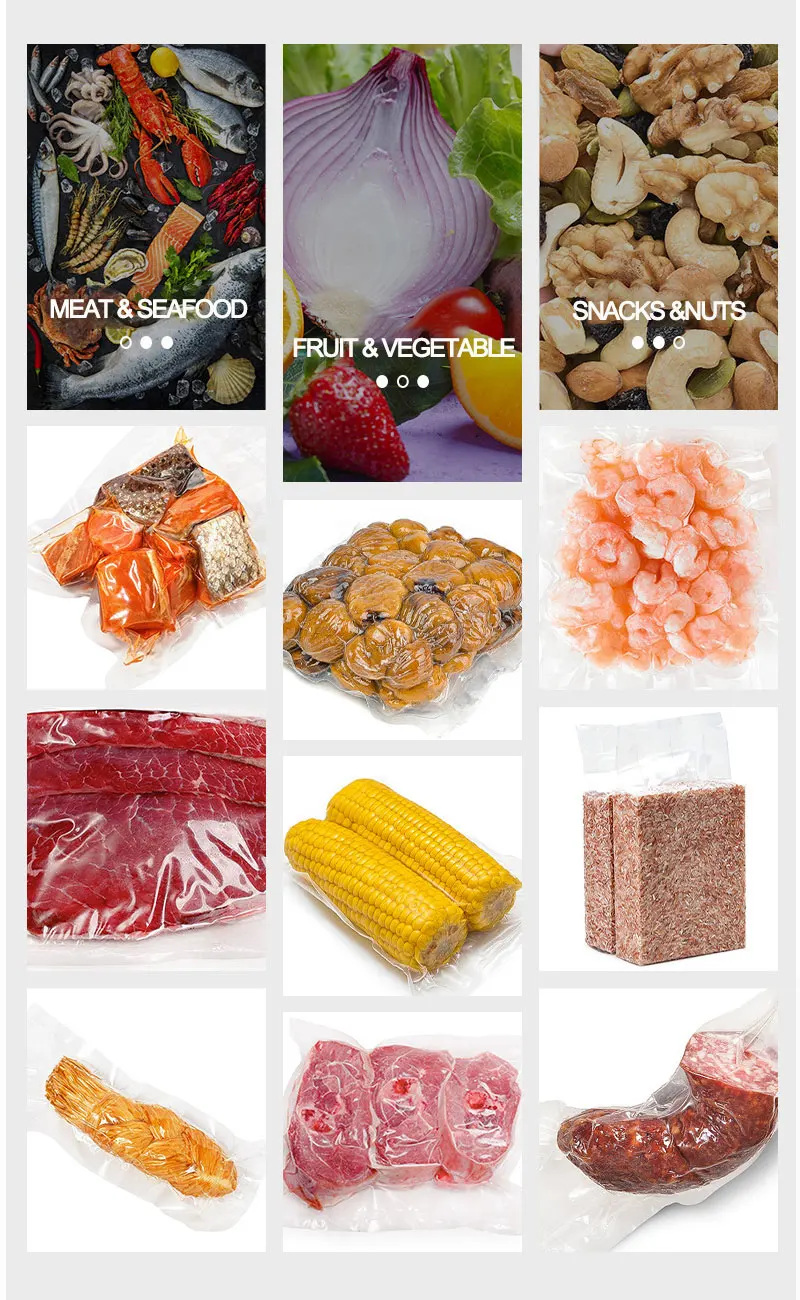

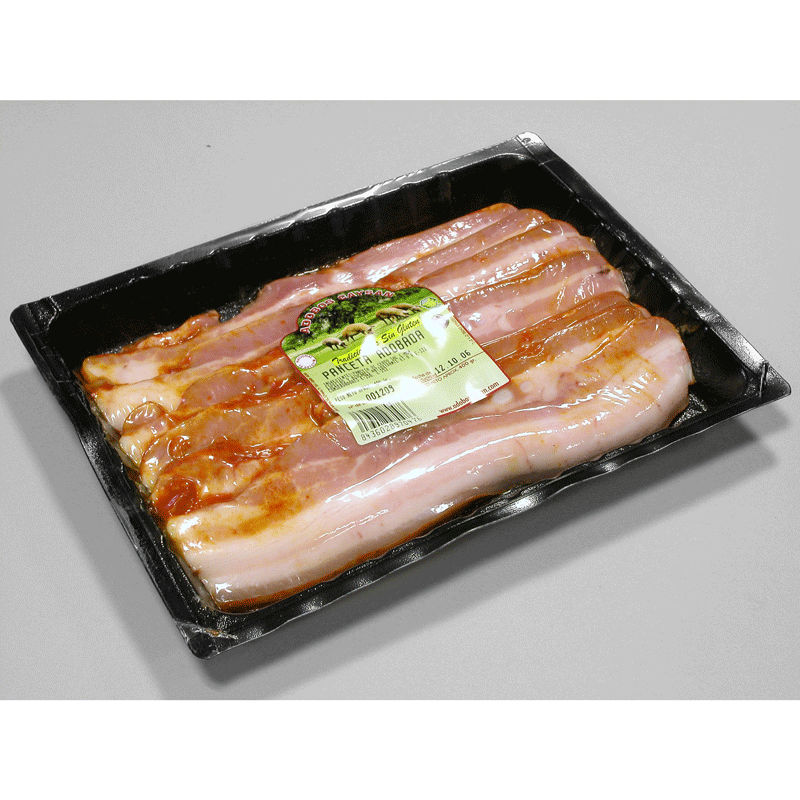

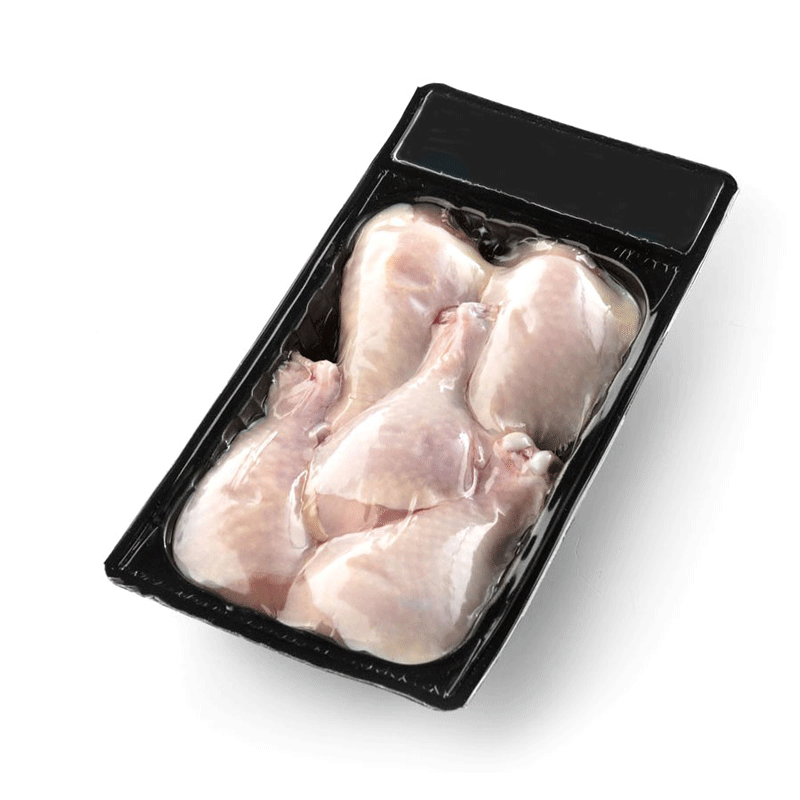

Packaging Sample Show

Q2.: Do you have any certifications for your products and your company?

A2: Yes. We have CE certifications, ISO9001, ISO14001.

Q3: The power supply in my country is different from that is in China, so I'm worrying if I could use the machine in my factory?

A3: Please don't worry about this. We customize every machine to make sure they are in accordance with your local power supply. You can use the machines wihtout any problem.

Q4: How long can I receive the machine if I make an order?

A4: The leading time is different, depends on machine type and production schedule.

Usually, leading time for thermoforming packagin gmachine is 15-30 days;

leading time for inline autoamtic MAP machine is 10-25 days;

leading time for vertical MAP machine and chamber vacuum packing machines are 5-15 days.

Q5: I'd like to visit your factory, how can I easily find your location, and what's the route to your factory?

A5: Your are very welcome to visit our factory.

Our location is: No. 458 Changzhan Road, Zhucheng, Shandong, China, 262200.

Your can easily find our location by searching 'SHANDONG KANGBEITE ' at google map.

Our nearest airport and railway station is Qingdao, a 2 hour's drive way.

It takes 2 hours flight from Shanghai to Qingdao, 4.5 hours flight from Guangzhou to Qingdao.