Factory Customized Automatic Food Fruit Cherry Tomato Packaging Seal Machine

- Model No.: KBT450/1S, KBT450/2S

- Tray maximum size: Customer provide

- Film roll width(mm): According to tray size

- Film roll diameter max.(mm): 280

- Speed (packs/hour): 300-400, 500-600

- Power supply: 3 Phase, 380V / 50HZ(can be customized)

- Compressed air(Mpa): 0.6-0.8

- Total power(kw): 7.5KW

- Vacuum pump: Busch or Rietschle, 100

- Gas exchange rate: ≥ 99%

- Residual oxygen: 《 0.5%

- Machine size (mm): About 1600*1600*1650, About 1800*1600*1650

- Machine weight (kg): About 650, About 850

- Overview

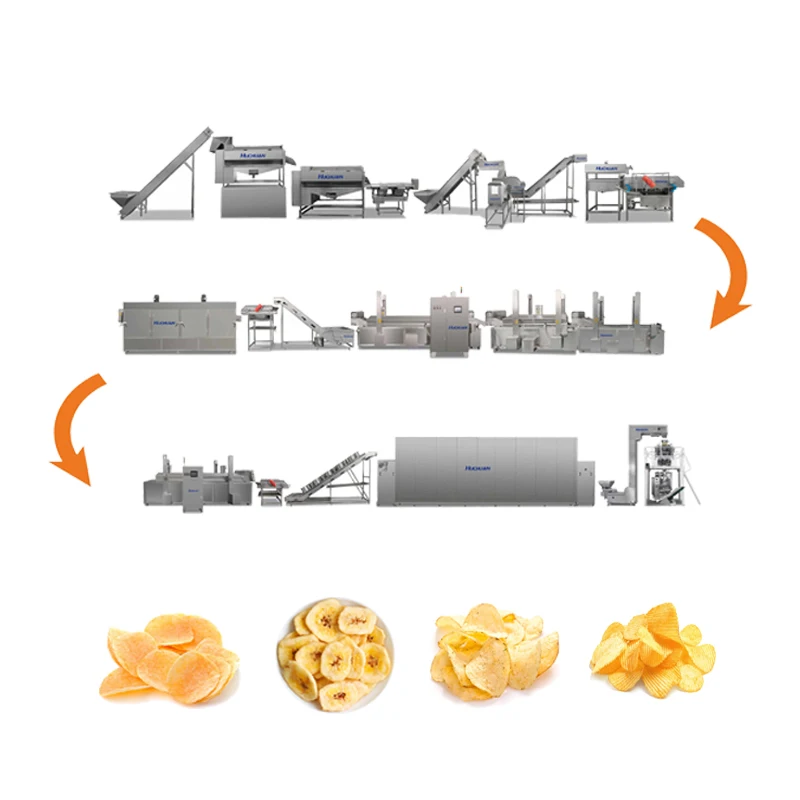

- Recommended Products

It's ideal packaging solution for various containers, including plastic trays, cups, bowls, etc.

detection, weighing, labeling system.

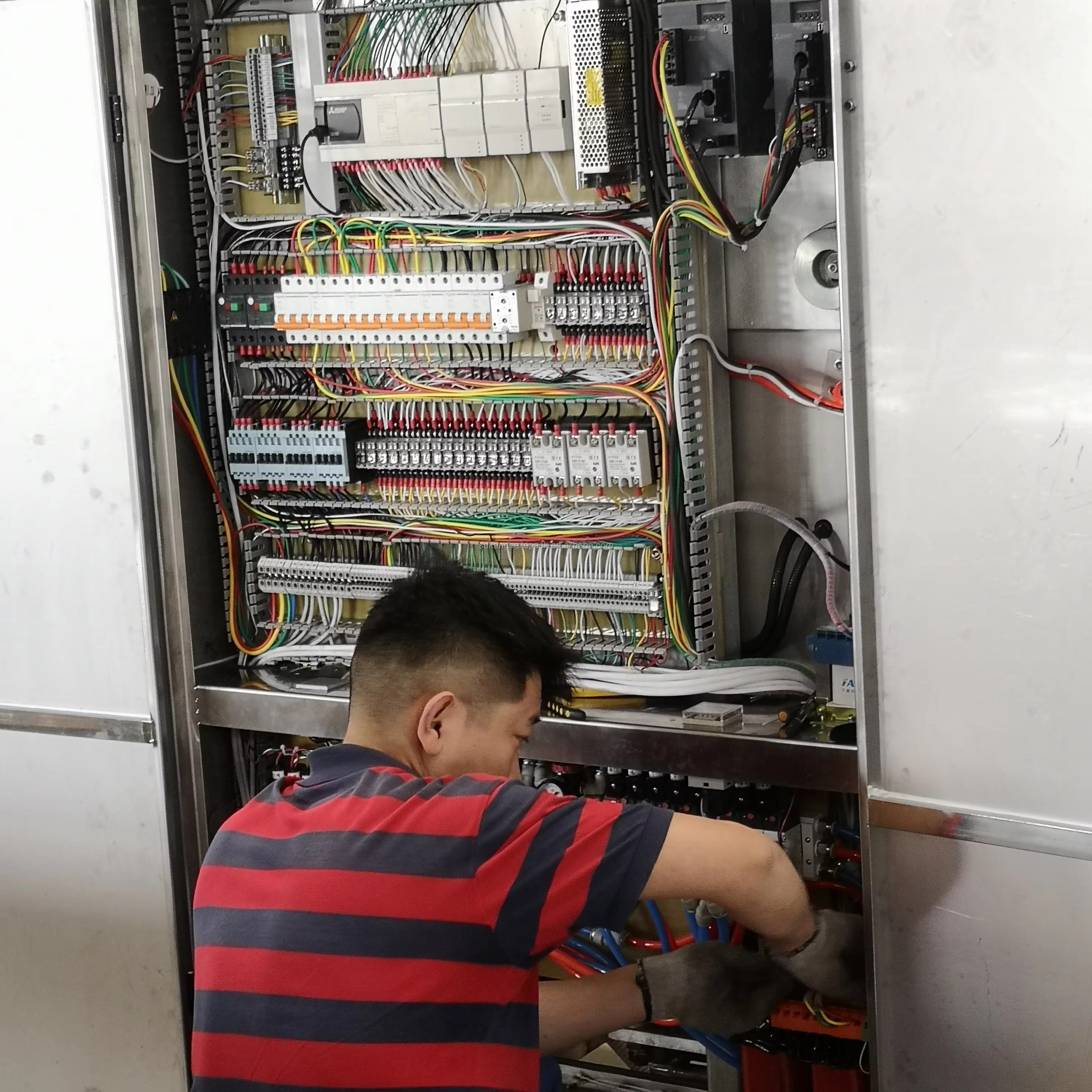

* Control system: Use MITSUBISHI 3GA20MT memorable PLC, together with MITSUBISHI touch screen, easy to setup and modify motions

and parameters. Motions are driven by MITSUBISHI high precision positioning servo motor, ensures 100% accuracy and stability.

* Temperature control system: MITSUBISHI 4 channel temperature control module, higher precision than temperature control button

system; Overheating alarm; Split type heating plate with grids, guarantees better sealing quality.

* Molds: Aluminum magnesium alloy molds, high strength, durable, corrosion proof.

* Photoelectric tracking system: Ensure 100% accurate in printed film sealing; Automatically skip the line with empty trays,

misplaced trays, missed trays. Remarkably enhance machine performance.

* Whole machine is made of SUS304 food grade stainless steel with more strength, more stability, no deformation.

* Safety: Equipped with emergency stop; Alarm; Open-phase protector; anti-phase protector.

* Imported silicone grease sealing ring, guarantees better sealing quality.

* Cutting system: Specially designed cutting system, integrated alloy blade, longer service life, easy to change.

|

Model No.

|

KBT450/1S

|

KBT450/2S

|

KBT450/2S

|

||||

|

Tray maximum size

|

Customer provide

|

||||||

|

Film roll width(mm)

|

According to tray size

|

||||||

|

Film roll diameter max.(mm)

|

280

|

||||||

|

Speed (packs/hour)

|

300-400

|

500-600

|

|||||

|

Power supply

|

3 Phase, 380V / 50HZ(can be customized)

|

||||||

|

Compressed air(Mpa)

|

0.6-0.8

|

||||||

|

Total power(kw)

|

7.5KW

|

||||||

|

Vacuum pump

|

Busch or Rietschle, 100

|

||||||

|

Gas exchange rate

|

≥ 99%

|

||||||

|

Residual oxygen

|

《 0.5%

|

||||||

|

Machine size (mm)

|

About 1600*1600*1650

|

About 1800*1600*1650

|

|||||

|

Machine weight (kg)

|

About 650

|

About 850

|

|||||

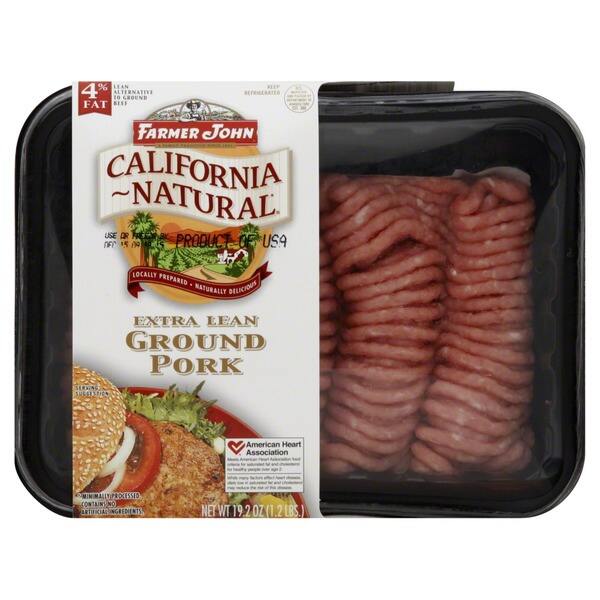

Packaging Sample Show

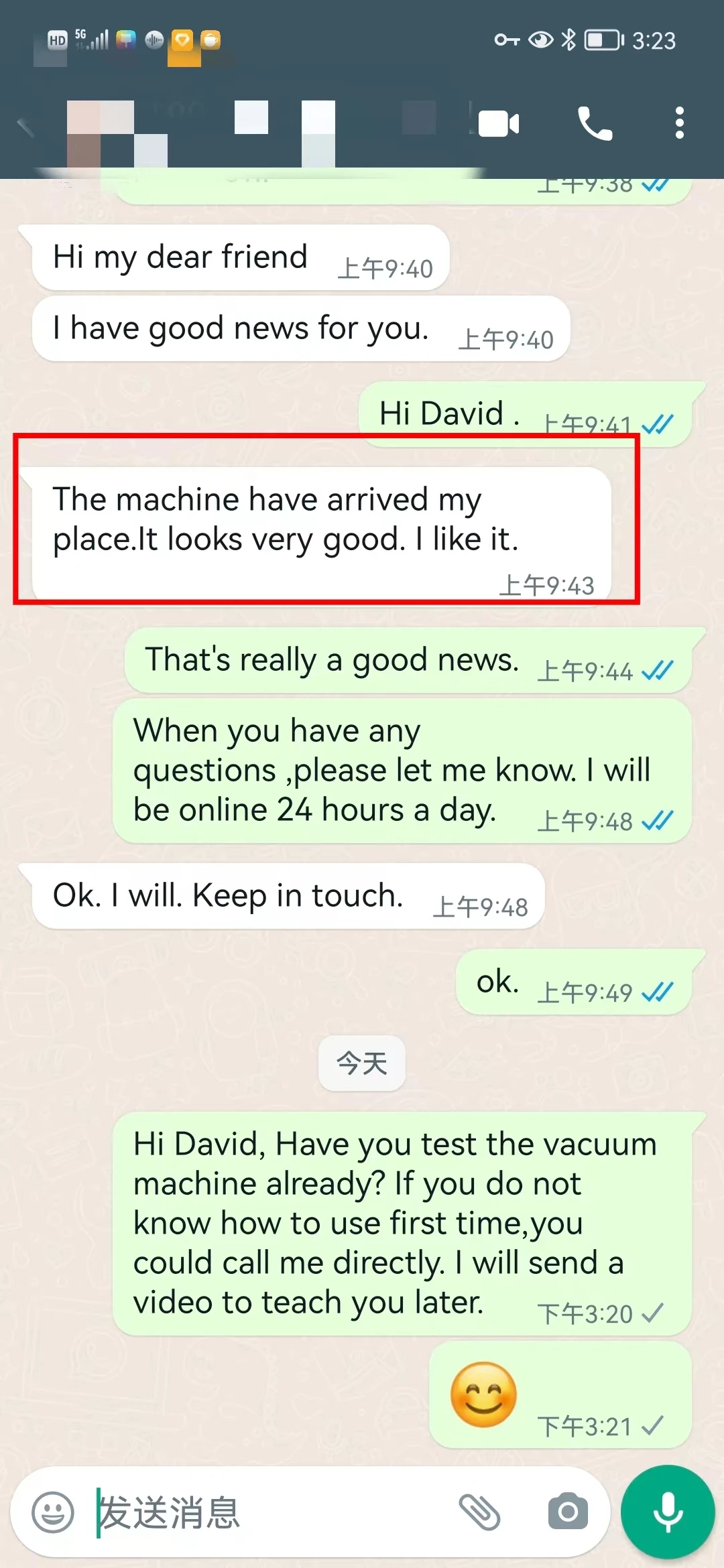

Q2.: Do you have any certifications for your products and your company?

A2: Yes. We have CE certifications, ISO9001, ISO14001.

Q3: The power supply in my country is different from that is in China, so I'm worrying if I could use the machine in my factory?

A3: Please don't worry about this. We customize every machine to make sure they are in accordance with your local power supply. You can use the machines wihtout any problem.

Q4: How long can I receive the machine if I make an order?

A4: The leading time is different, depends on machine type and production schedule.

Usually, leading time for thermoforming packagin gmachine is 15-30 days;

leading time for inline autoamtic MAP machine is 10-25 days;

leading time for vertical MAP machine and chamber vacuum packing machines are 5-15 days.

Q5: I'd like to visit your factory, how can I easily find your location, and what's the route to your factory?

A5: Your are very welcome to visit our factory.

Our location is: No. 458 Changzhan Road, Zhucheng, Shandong, China, 262200.

Your can easily find our location by searching 'SHANDONG KANGBEITE ' at google map.

Our nearest airport and railway station is Qingdao, a 2 hour's drive way.

It takes 2 hours flight from Shanghai to Qingdao, 4.5 hours flight from Guangzhou to Qingdao.